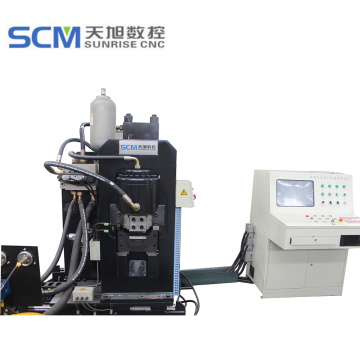

CNC Punching Marking Cutting Machine for Flat Bar

Basic Info

Model No.: TPL8004

Product Description

CNC Hydraulic Flat Bar Punching, Marking and Cutting Machine Model TPL8004

Applicable Industry:

The machine is the automatic special equipment used for flat bar steel marking, punching, and shearing mainly in the field of angle steel tower industry.

Product Feature: 1. Adopt CNC technology,servo motor infeeding,with high efficiency, stable workpiece precision. 2. Key hydraulic,pneumatic and electric parts all imported. 3. Easy programming and can directly use the program data made by lofting software. 4. Computer with Chinese/English interface,easy operation, and can display the drawing of workpiece. 5. All marking,punching and shearing in automatic completeness. 6. Only need to input size of workpiece,diameter of holes and quantity of workpiece when edit program. 7. Fast marking speed. 8. Flat end with single-balde cutting; Circular arc end with double-blade cutting; 9. With self-diagnosis failures function.

Specifications:

| Model | TPL8004 |

| Max.Workpiece length(mm) | 8000 |

| Workpiece width(mm) | 40~120 |

| Max.punching diameter(mm) | Φ26 |

| Oval hole(mm) | 22X50 |

| Max.thickness(mm) | 12 |

| Punching force(KN) | 1200 |

| No. of punching die-station | 3 |

| Marking force(KN) | 1000 |

| No. of marking die-station | 1 |

| Character size(mm) | 14×10×19 |

| No. of character | 12 |

| Cutting force(KN) | 1200 |

| Cutting Mode | Flat end with single-blade cutting; Circular arc end with double-blade cutting |

| Feeding mode | CNC carriage |

| Feeding speed(m/min) | 60 |

| Precision | According with GB2694-2010 |

| Programming mode | Input by keyboard, RS232 interface, floppy disk and USB interface |

| Program function | Error display |

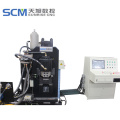

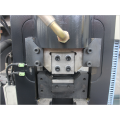

Products Show:

Shearing Unit

Shearing Unit

Punching Unit

Punching Unit

Feeding conveyor and worktable

Feeding conveyor and worktable

Automatic Feeding Carriage

Automatic Feeding Carriage

Our Service:

Installation:

The seller shall send one engineer to the buyer's country for installation, commissioning and training. The buyer is responsible to provide all necessary equipments for handling and lifting the machine parts before seller's engineers go to the buyer's plant. In addition, the buyer should provide workers to support in installation activities, under supervision from the seller's engineers.

Commission:

The Supplier should give drawings and Other Details of material/preparation required for installation of machinery which the buyer has to prepare and keep ready before the machine arrives at the buyer's factory. Installation and commissioning can be finished within 5-10 days for above machine generally.

Training:

Training will include training on computer programming, machine operation and troubleshooting. The training time is at most 5 days for this machine. The buyer should arrange no less than two people for accepting training. After training, the buyer should sign the "Receiving & Inspection Report" supplied by the seller to demonstrate the successful finish of commissioning and acceptance of the buyer.

Product Categories : Punching Machine > Plate Punching Machine